Equipment

WAREHOUSE AREA

1 INCOMING MATERIAL STATION

(ESSEGGI MODELLO ISM 2.0)

6 AUTOMATIC WAREHOUSE

(ESSEGGI MODELLI ISM ULTRAFLEX 3600 E 3900)

6 WAREHOUSE PICK TO LIGHT

(ESSEGGI MODELLO ISM 500)

1 X-RAY COMPONENT COUNTING SY-

STEMS

(VJ ELECTRONIC XQUIK III)

3 DRY CABINET

(TOTECH MODELLO SUPER DRY SD+ 1104-22)

1 BAKING OVEN

SMT department

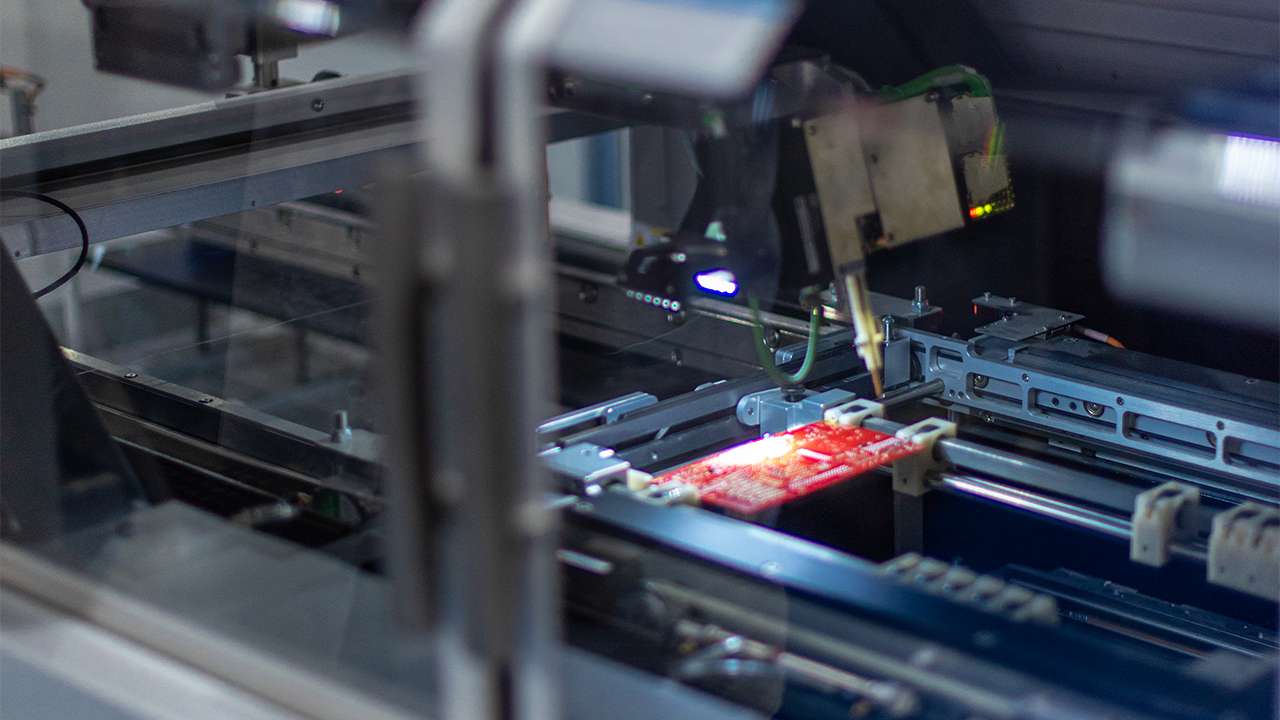

3 SMT LINES

(6 JUKI P&P RS1)

3 SCREEN PRINTER DEK

(HORIZON 03I AND 03IX)

2 SPI

(TRI TR7007QI)

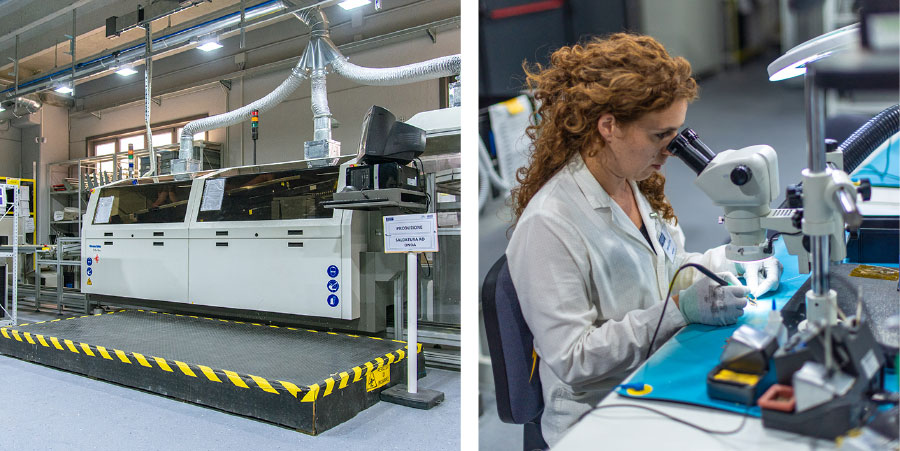

2 REFLOW SOLDERING SYSTEMS

(VITRONICS CENTURION CT 930)

1 VAPOUR PHASE SOLDERING SYSTEM

(ASSCON VP800)

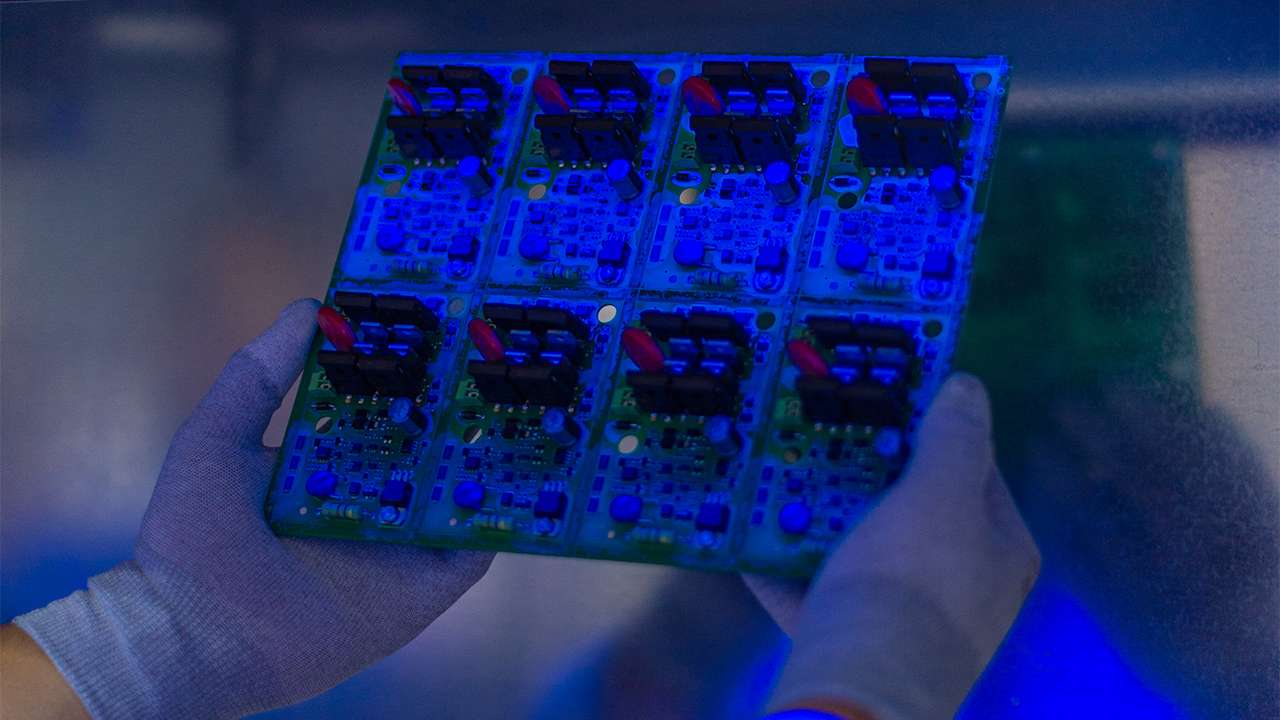

2 AOI

(TRI TR7500 SIII 3D)

2 SEMIAUTOMATIC TAPE AND REEL SYSTEM

(ADVANTEK MODELLO ATR 1000/ QUASER Q610)

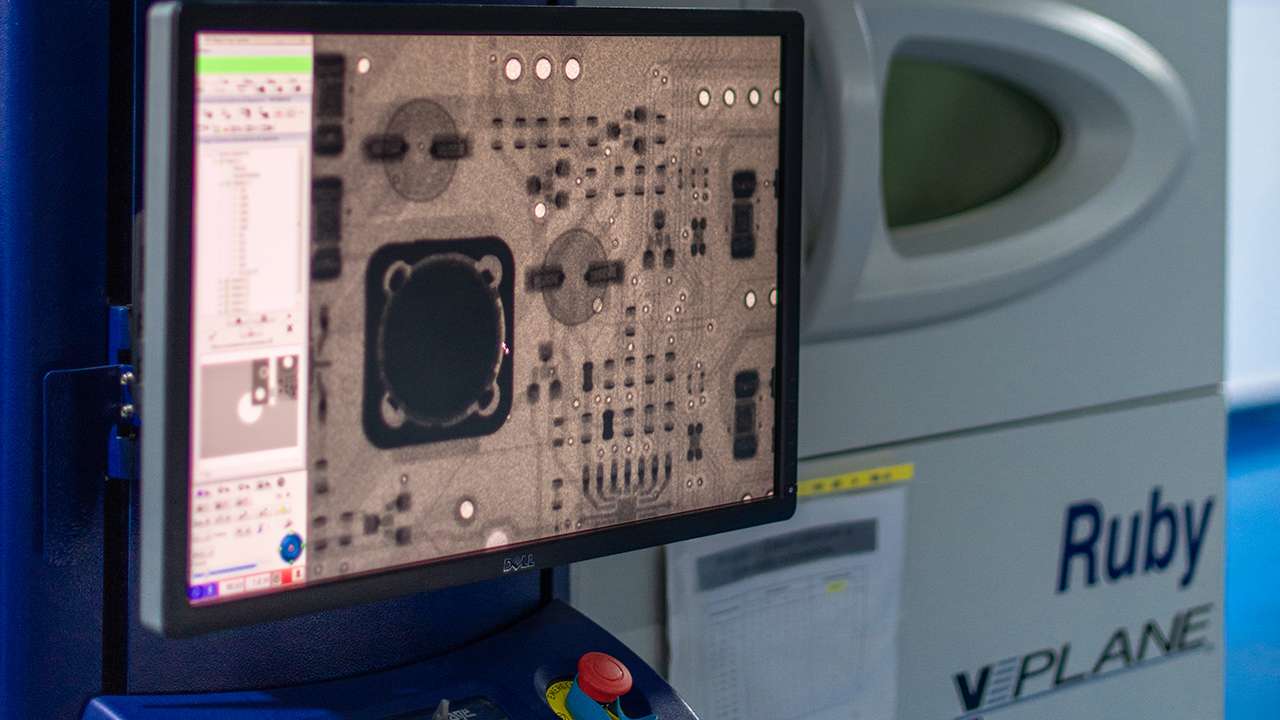

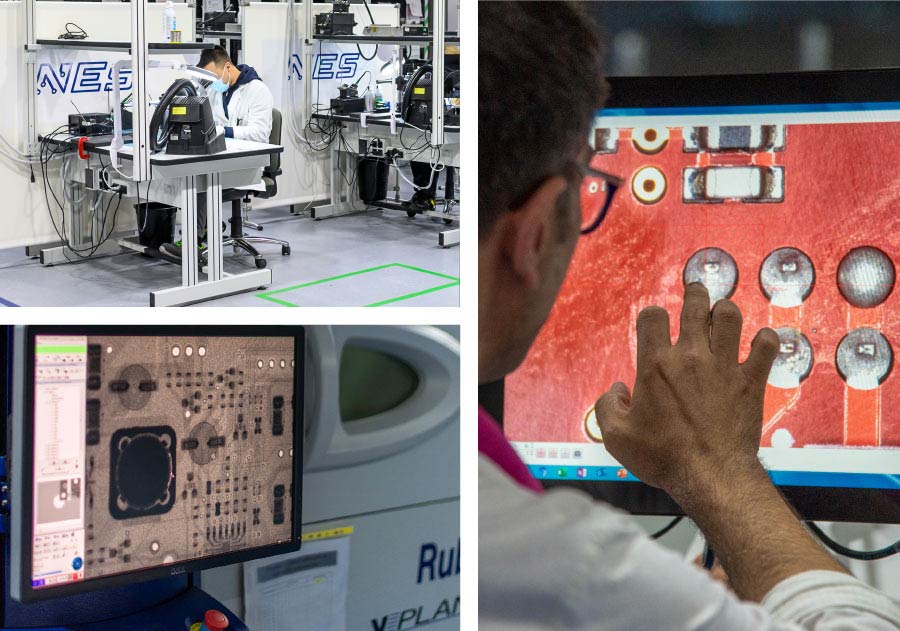

1 XRAY

(NORDSON DAGE RUBY XD7600NT)

1 ULTRASOUND WASHING MACHINE

(SRA T. UC 150D)

1 REWORK BGA

(ERSA HR600 AND REBALLING KIT)

Tht department

1 SELECTIVE SOLDERING SYSTEM

(ERSA VERSAFLOW 3/45)

1 WAVE SOLDERING SYSTEMS

(VITRONIC SOLTEC DELTA WAVE 6622)

1 THT INSPECTION

(A01 6.0)

3 DEPANNELING PCB

(AUROTEK AUO-3000C), PIERGIACOMI DPF-300,

MAESTRO 4S)

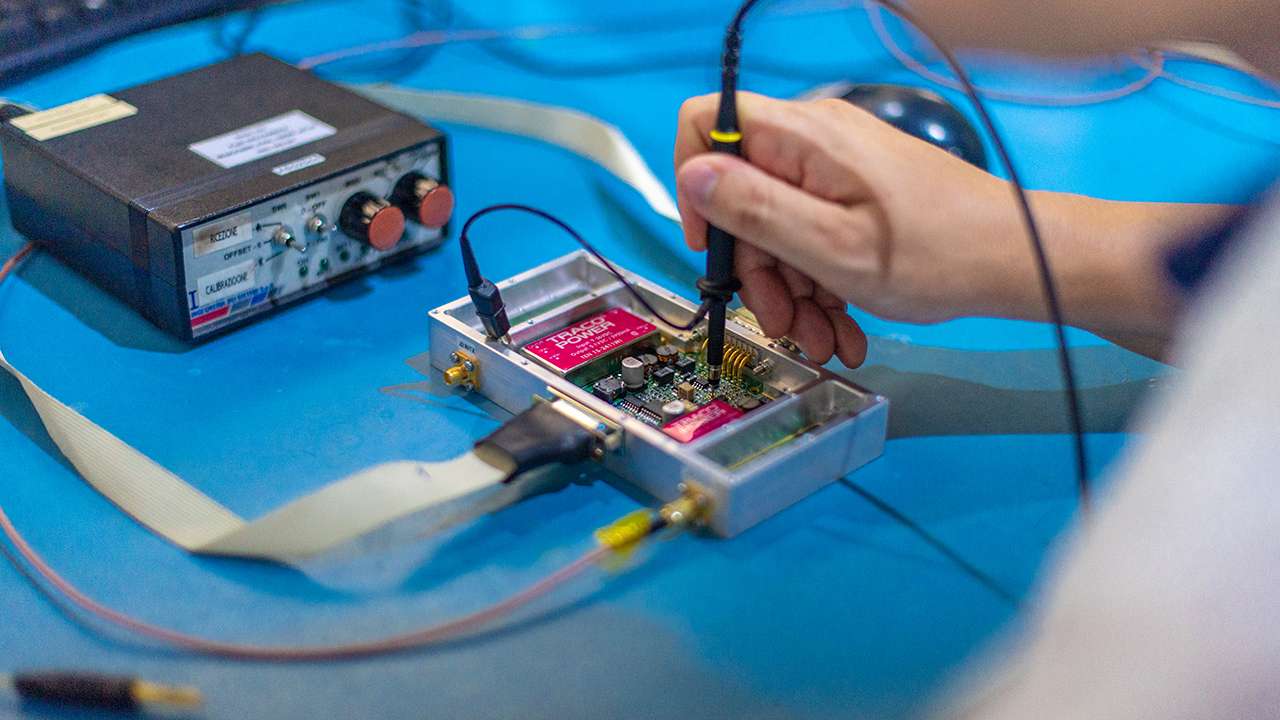

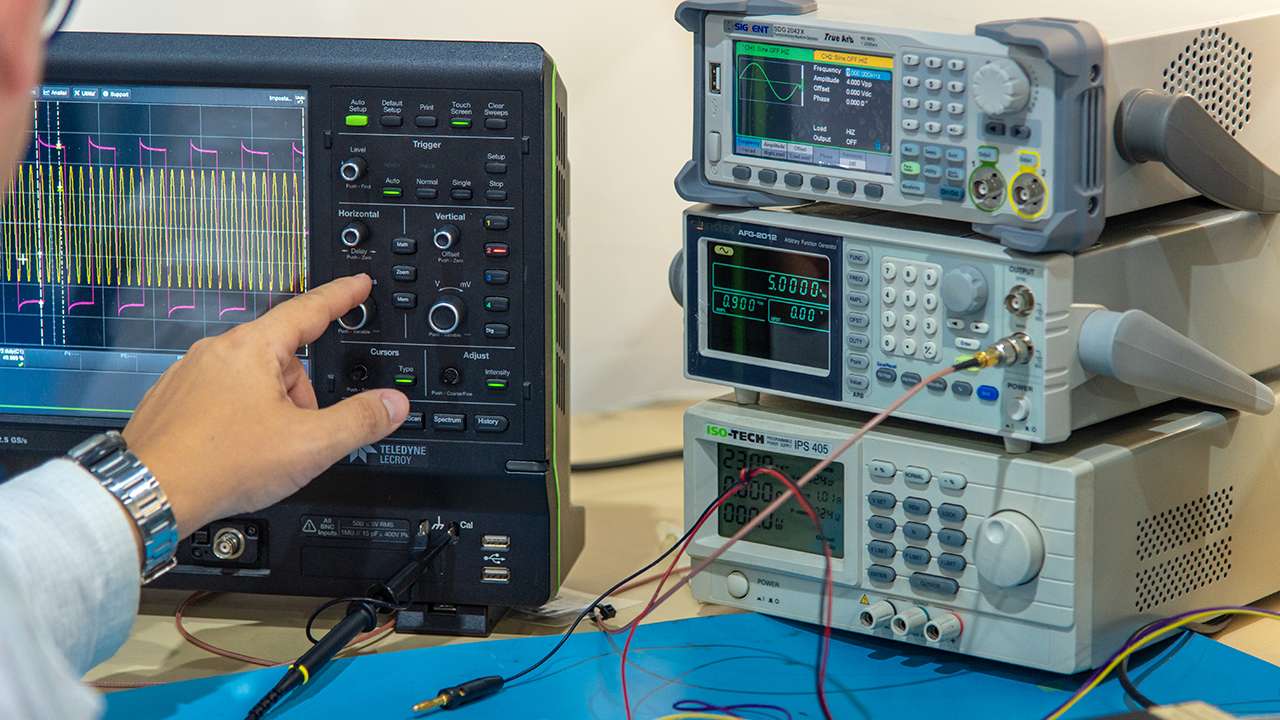

TEST department

1 CLIMATIC CHAMBER

(ANGELANTONI DISCOVERY DM600 C ES)

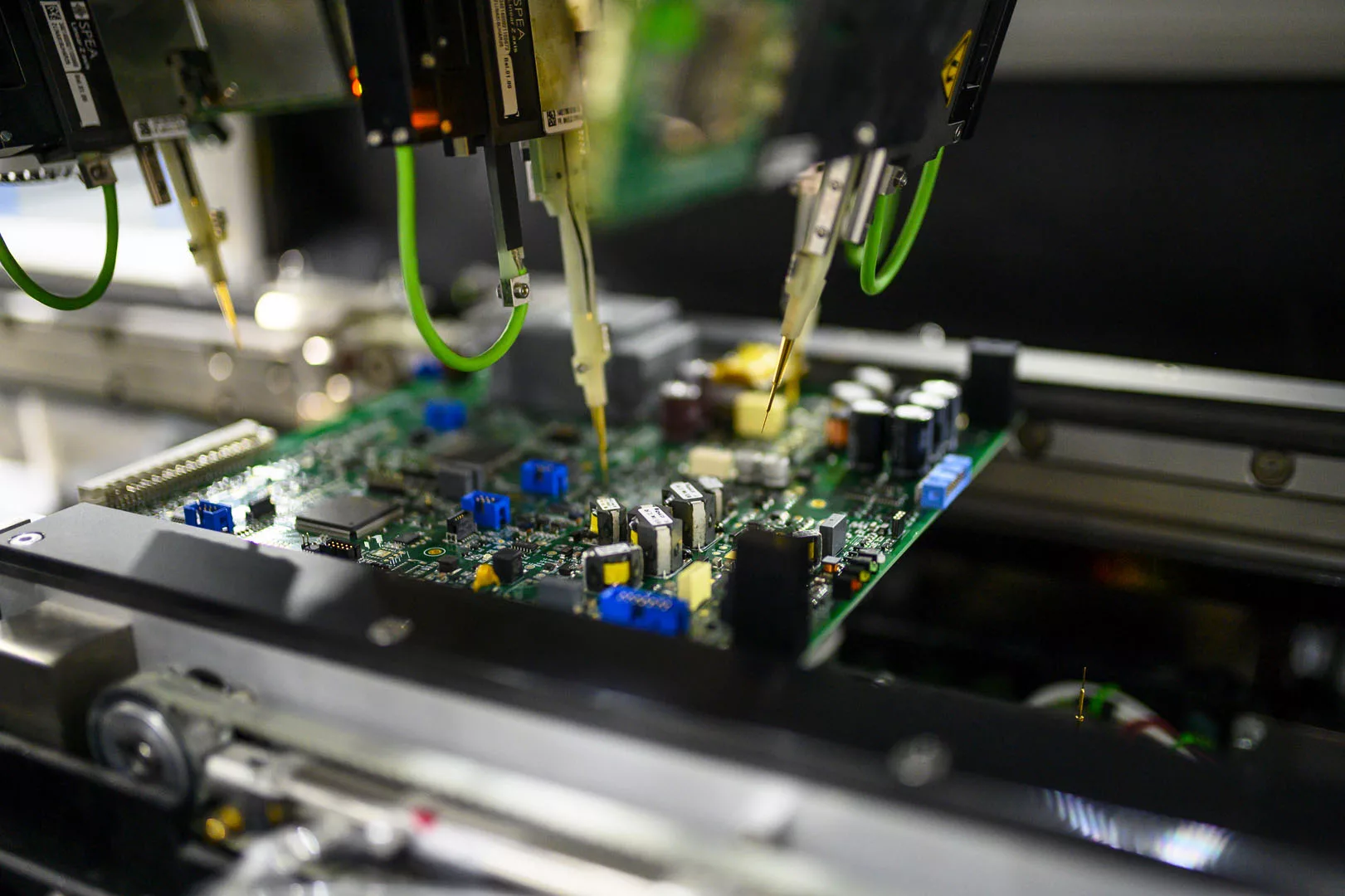

1 FLYING PROBE TESTER

(SPEA 4060S2)

2 FIRST ARTICLE INSPECTION SYSTEM

(EXTRA EYE X3020)

CAD, XJTAG, LABVIEW

CONFORMAL COATING Department

3 SELECTIVE COATING SYSTEMS

(PVA DELTA 8) (PVA DELTA 6)

3 INFRARED HEAT CURING CHAMBER

(PVA IR2000, LEMME THEMIS 2000)

1 COATING CABIN

(CUSTOM)

1 CLEANING SYSTEM

(PBT SUPER SWASH)

1 IONIC CONTAMINATION TEST STYSTEM

(SCS IONOGRAPH 500M STD)

2 TWO COMPONENTS RESIN DISPENSER

(CONTALDI INDUMIX IA)

1 OVEN MPM

(M400-VF)