WHY NES

fully integrated service

The customer who relies on NES can find complete support in the realization of his project. Starting from client’s idea up to the realization of the finished product, NES is able to offer every single step of the entire processing cycle internally

certified company

NES has been released with the main certifications such as ISO 9001, EN 9100, IRIS, ATEX etc. to ensure quality in development and production. Furthermore, the staff is highly qualified and meets certifications such as IPC 600, IPC 610T, IPC 7711/7721, J-STD-001 etc. as well as it is annually subject to checks by the certifying body RINA

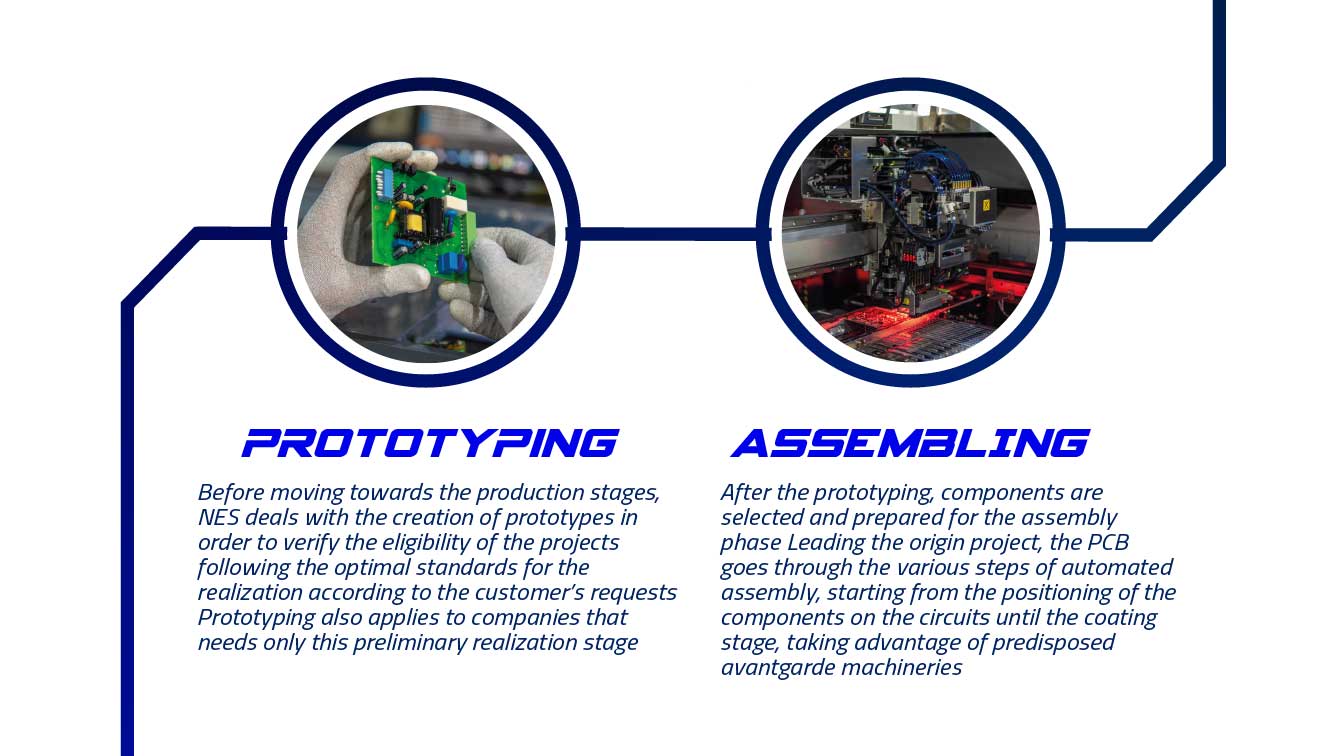

fast prototyping

Based on the complexity of the product and the components market availability, NES is able to provide a complete prototyping service in 2/4 days from the release of the first documentations

always OPEN AND ready

NES is always ready and available to offer its services any time of the year

vanguard and know how

By investing every year, NES is continuously updated with the most modern production equipment, increasingly expanding the range and quality of the services offered. Thanks to its skills it is able to provide customers with the best solutions for the realization of their projects

trasparency

Loyal customers have the possibility via an internet dashboard made available by NES, to follow the work progress and to obtain informations about production line in real time

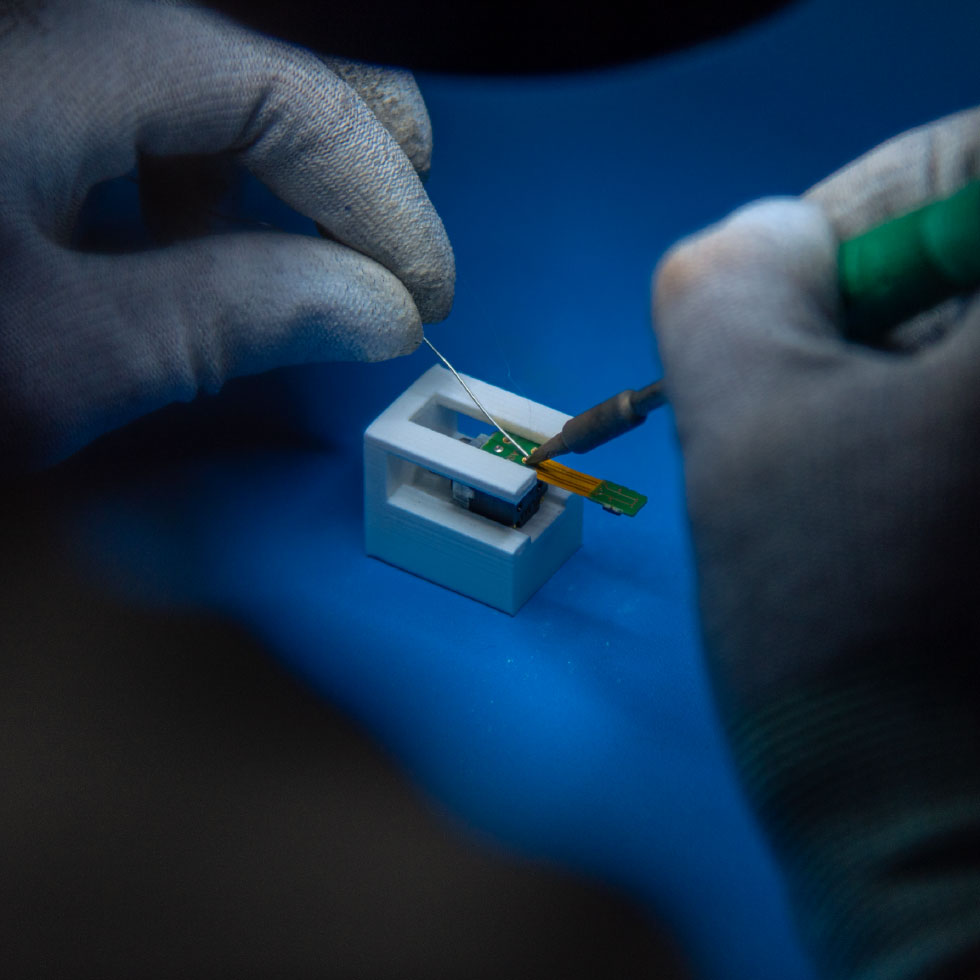

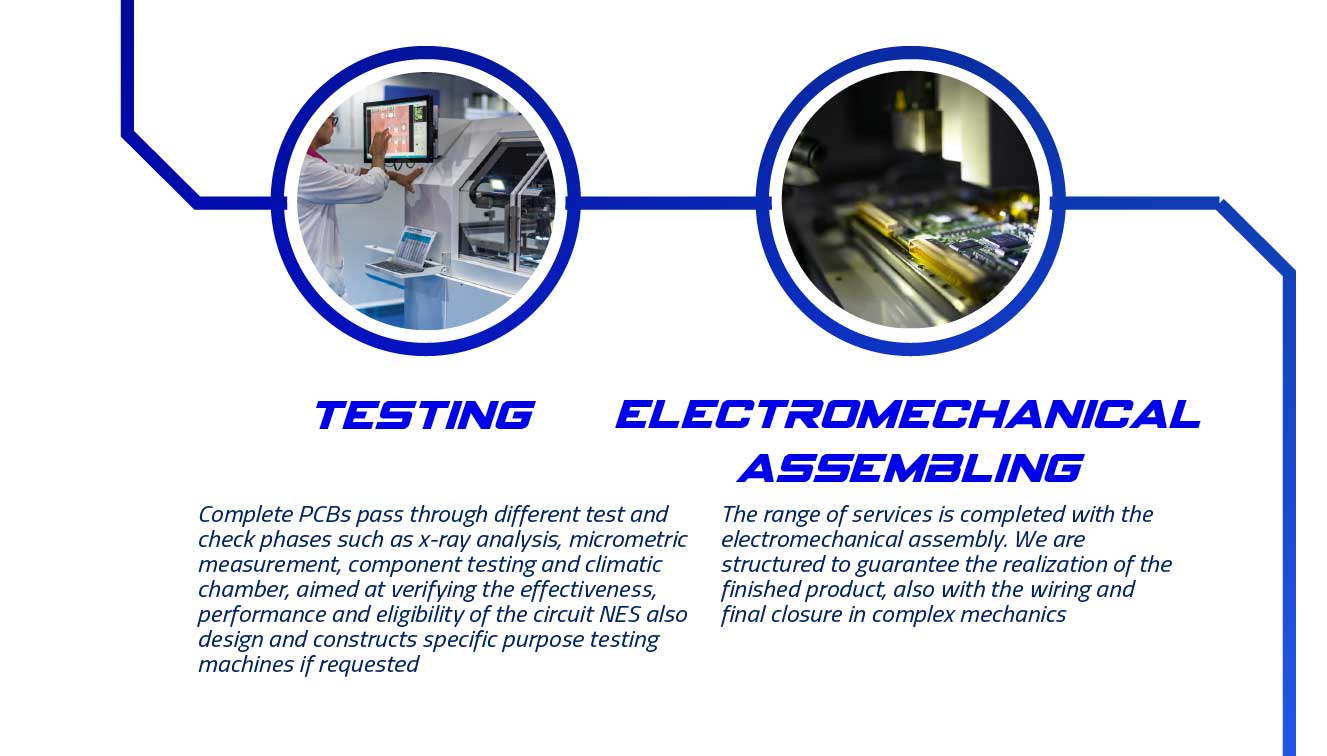

test engineering

NES designs testing strategies for a product and even complex equipments for testing the product itself, providing certifications and manuals

solidity

NES can guarantee long-lasting partnerships to customers, thanks to the adoption of medium and long term based strategies and thanks to a careful economicfinancial management that made the company solid

flexible stock capabilities

Thanks to his financial strenght, NES is capable to offer storage of even halfprocessed products for their clients; the opportunity of completing the assembly even few days before the delivery gives to the customers the chance to place their orders with a long term timing

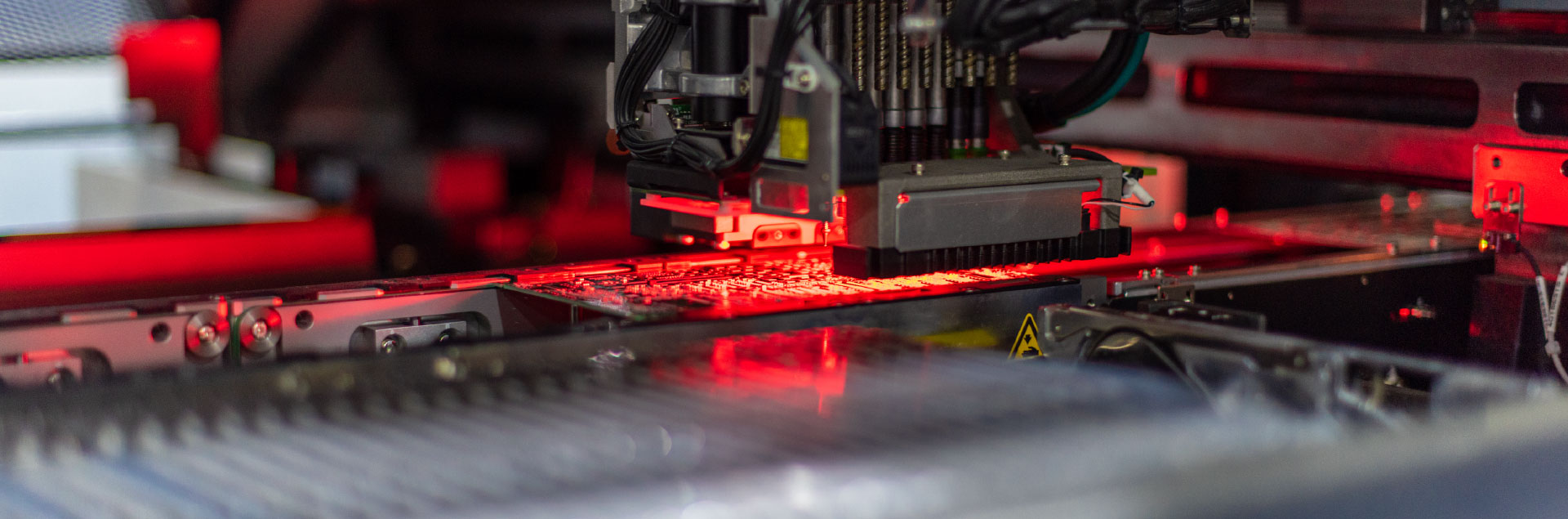

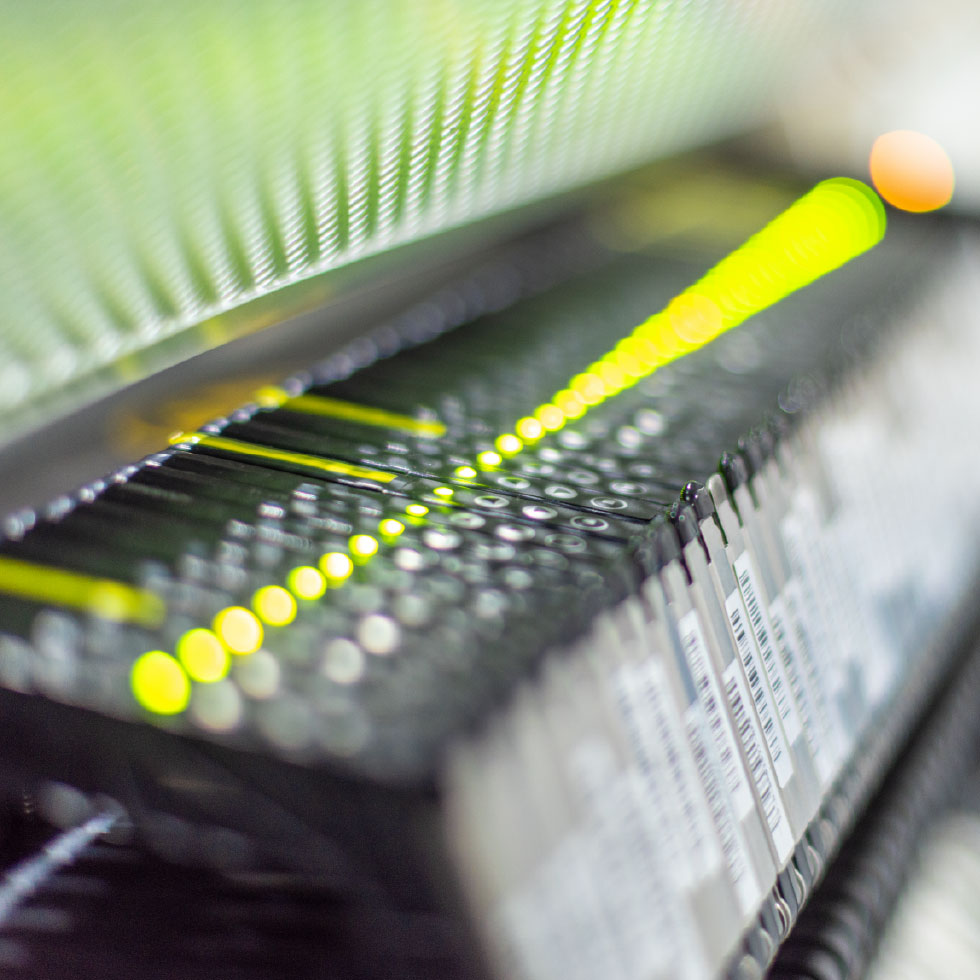

fast smt production

With three indipendent SMT production lines with a power rate of 160.000 components mounted per hour, NES is well capable of handling high manufacturing numbers without even interfeering with his prototyping line

national logistic coverage

Thanks to his two facilities based in Caserta and Bologna, NES guarantees logistic coverage upon the whole national territory, approaching managerially and physically to his clients

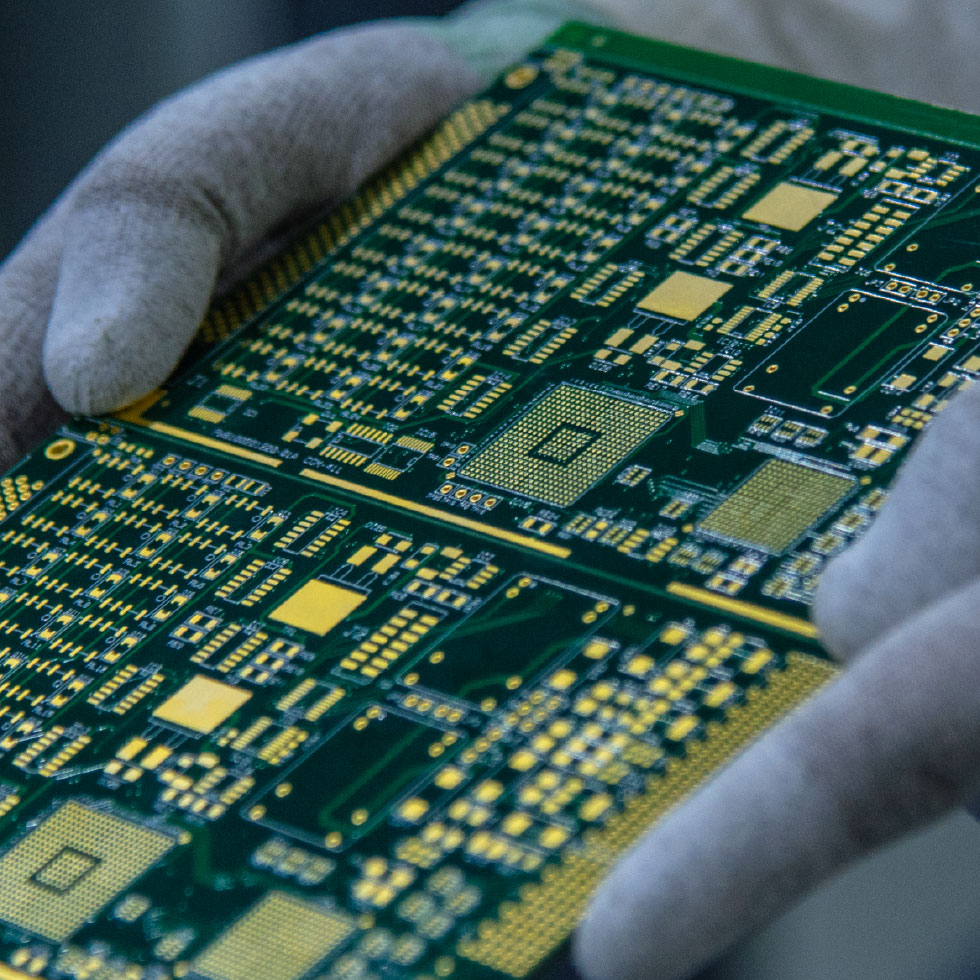

– PRODUCTION –

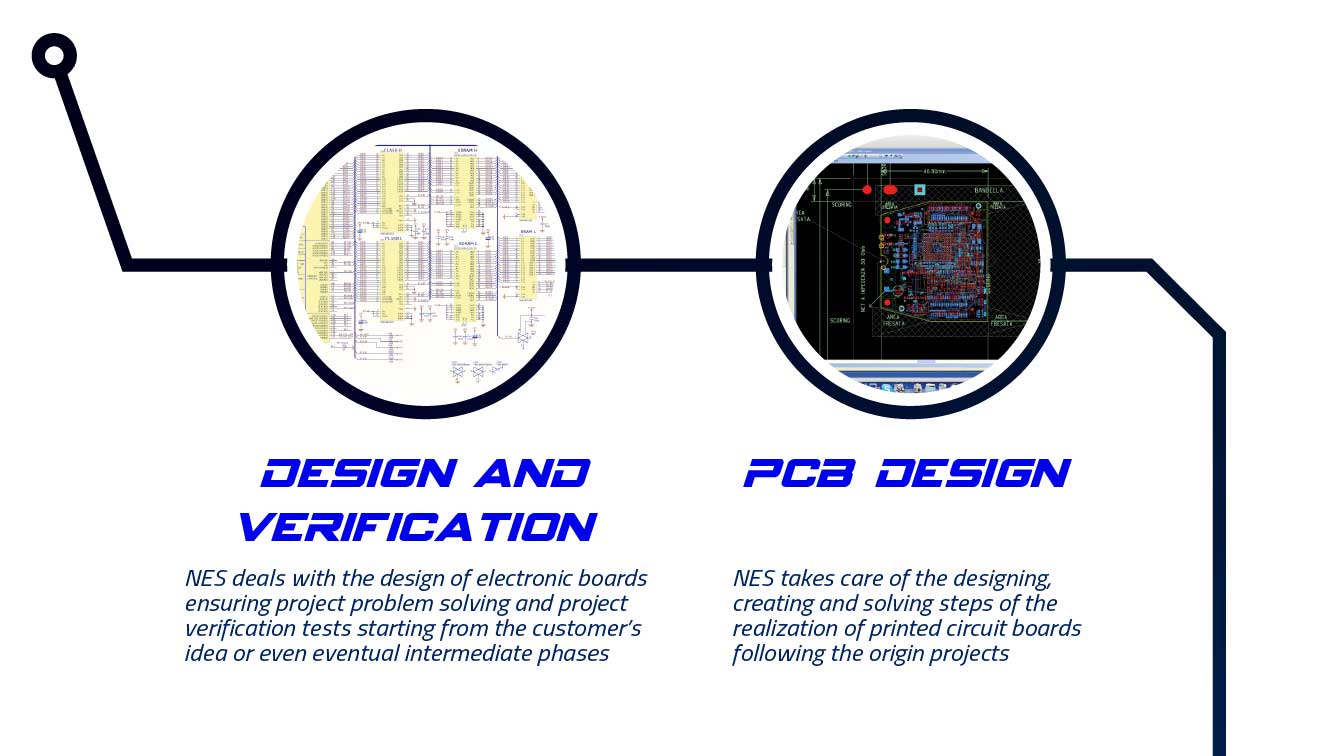

– SERVICES –

PRODUCTION LAYOUT

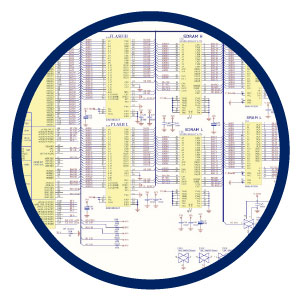

services detail